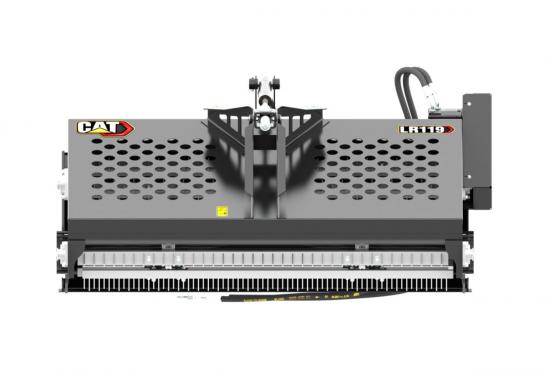

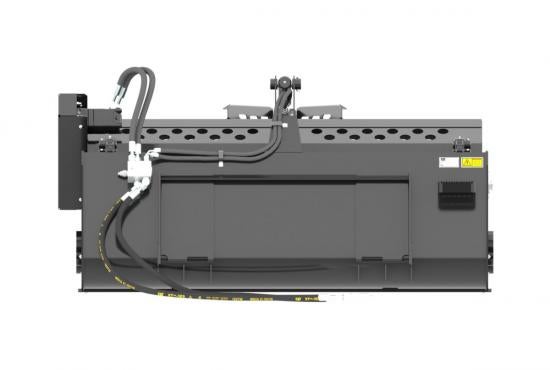

Mulcher Special

FREE REPLACEMENT TEETH AND EQUIPMENT PROTECTION PLAN

Get a free set of primary replacement teeth and an additional year of equipment protection!

Buy a new 300 or 400 series Cat Mulcher to take advantage of this offer. The offer of free primary replacement teeth covers your choice of carbide or bite limiter style, and does not include side cutters. The Equipment Protection Plan will be auto enrolled at no cost to you. Offer ends 12/31/23.*

VisionLink: Complete Visibility to Manage Your Entire Fleet

VISIONLINK TECHNOLOGY

Turn Data into Action

Are you ready to take the guesswork out of fleet management? VisionLink® delivers easy-to-understand actionable insights to help you make informed decisions at every turn. Get the most out of your entire fleet - from one single, intuitive, and trusted application.

Contact Us

Download Brochure

VisionLink Portal

The Power to Take Action

ENTIRE FLEET VISIBILITY

- Get actionable data insights for all assets regardless of make.

- Manage mixed OEM fleets via one interface.

- Monitor owned, rented, or leased assets.

UP-TO-DATE ASSET TRACKING

- Track location, operating hours, fuel levels, health issues, and overall utilization.

- View work tool attachment locations across multiple worksites and measure working hours to predict the need for tool maintenance.

MAXIMIZE UPTIME

- Monitor equipment health, fault codes, fluid analysis, and inspection due dates.

- Reduce unplanned downtime with critical alerts.

- Order parts and schedule service within the platform.

OPTIMIZE UTILIZATION

- Manage according to projects, groups, or geofences.

- Set utilization targets and monitor performance.

- Make informed, databased decisions to reduce operating costs.

BETTER DATA, BETTER DECISIONS

Eliminate Guesswork

VisionLink takes the guesswork out of fleet management with key insights to maximize performance—regardless of fleet size or equipment manufacturer.* VisionLink delivers timely equipment data seamlessly to your desktop or mobile device from a convenient centralized solution. With interactive dashboards, VisionLink makes it easier for operations of all sizes to make informed decisions at every turn.

Designed for Fleets of 1 to 100+

To get started with VisionLink, activate the built-in hardware on new Cat equipment. For older Cat assets and other OEM brands, install Product Link™ devices or integrate data from existing OEM or third-party telematics providers using APIs. With the ability to make informed decisions that lower costs, boost productivity, simplify maintenance, and enhance jobsite safety, you get more done in less time for less money.

Note: A VisionLink subscription is required for equipment data reporting. Availability may vary by region and model.

* Data field availability can vary by equipment manufacturer.

HOW IT WORKS

Deliver Real Results

One Stop Solution

VisionLink is your one-stop platform for easy-to understand data and actionable insights to optimize your assets across your entire fleet.

Mixed Fleet Management

Manage all your assets - regardless of brand. Connect to 3rd party and other OEM data providers or import OEM assets using Cat Product Link devices

API Connections

Application Programming Interfaces (APIs) allow VisionLink to connect with other software applications using ISO (AEMP 2.0) standards or custom APIs for more advanced data features such as geofences

Mobile App

Stay on the go and manage your fleet - wherever you are. Pull up VisionLink on your desktop or mobile app for iPhone and Android users.

In-App Support

Navigate the app with confidence. VisionLink provides in-app help, FAQs, and tutorial videos to guide you on features and functions.

One Integrated Experience

VisionLink integrates with many Cat applications including Cat Inspect, Cat S∙O∙S, Cat SIS2 (Service Information System), and parts.cat.com. Further integrations are planned.

Cat Batteries

The reliability of your machine and automated equipment begins with a reliable battery. You need to have confidence that your battery will start your equipment every time, even in the most adverse environments and extreme temperatures. The best way to assure your commercial equipment will start is to install Cat Heavy Duty (HD), Cat General Duty (GD) or Stationary batteries that are manufactured to Caterpillar's high quality standards.

Contact Us

Buy Online

HEAVY DUTY (HD) BATTERIES

Cat Heavy Duty (HD) batteries are used in all Cat machines. With equipment operating in rough terrain, a battery must withstand extreme vibration. That’s why Cat HD batteries pass an exclusive 100-hour vibration resistance test, while competitive batteries meet either an 18 or 36 hour standard.

CAT HD BATTERIES EXCEED INDUSTRY STANDARDS IN ALL FIVE OF THE FOLLOWING STRINGENT TESTS:

- 100 hour vibration test

- 72 hour deep discharge/recharge cycle test

- 30 day complete discharge test

- Heavy-duty life cycle test

- Cold soak test

3-5X INDUSTRY STANDARD IN 100-HR VIBRATION TEST

Most other competing battery brands do not apply such demanding standards, or go through some of these rigorous tests. Maybe that's why Cat HD batteries are the highest-rated batteries in cold cranking amps (CCA) and reserve capacity available. We invest more time and resources to deliver the best battery possible to you - our valued customer. The end-result is a battery that lasts three times longer than other "competitive batteries."

GENERAL DUTY (GD) BATTERIES

LIGHT-DUTY, COMMERCIAL, AUTOMOTIVE AND RV BATTERIES

To meet your battery needs for light-duty commercial applications, Cat General Duty (GD) batteries are competitively priced and deliver outstanding value and performance. Browse through our large selection of 6 Volt, 8V, and 12V Cat GD batteries for the battery that best meets your needs.

6 VOLT, 8 VOLT, AND 12 VOLT BATTERIES FOR:

- Riding Mowers, Lawn Tractors and Gardening Tractors

- Light Trucks (Including but not limited to Minivans, SUV's, Pick-Up Trucks and Tow Trucks)

- Emergency Lights

STATONARY BATTERIES

LONG LIFE POWER SUPPLY BATTERIES

Valve Regulated Lead Acid (VRLA) batteries are critical to the proper operation of your back-up power supply. That' s why Cat Stationary Batteries are designed to provide power instantly in order to protect your sensitive computer and manufacturing equipment against possible damage from surges or dips in voltage or current. Our Stationary batteries can power essential hospital or mission critical loads during a power outage. They help assure that your power generators are compliant to meet NFPA 110 standards.

Absorbed Glass Mat (AGM) technology is at the core of our batteries. Puncture resistant glass mat separators absorb all the electrolyte, which lowers internal resistance and results in effective high-rate, short-term power. This protects against shorts and failures. Cat Stationary batteries provide the best possible power capacity and cell consistency, with long-lasting reliability.

Cat Stationary batteries have several design elements that also contribute to long life:

- More substantial plates are pasted from both sides to increase durability.

- Epoxy seal posts create a secure barrier that keeps acid inside, limiting corrosion and extending battery life.

- The reinforced polypropylene case and cover are heat sealed and factory tested for added durability and long-life performance.

- The result is a Stationary battery with a 10-year design life. The Cat Stationary battery goes through more than 250 quality control checks and tests to assure accurate capacity ratings that are required for your standby power systems. When you need a battery that provides high-rate short term power instantly Cat Stationary batteries provide peace of mind and value - year after year.

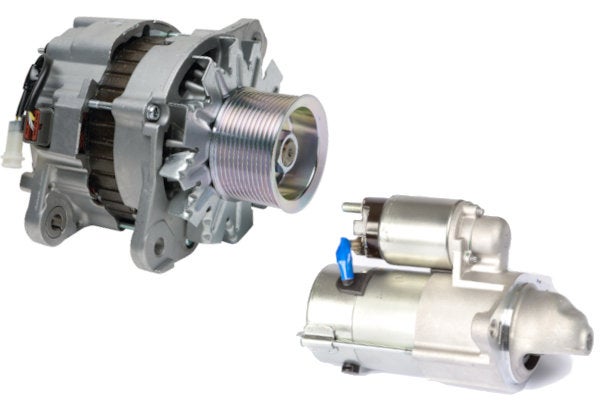

Cat Starters and Alternators

Cat Starters and Alternators Deliver Power and Reliability

Starters and alternators are engineered as part of a balanced electrical system. Computer-aided design, stress simulation, environmental validation, and 100% testing help ensure Cat starters and alternators work in unison with the rest of your Caterpillar engine components.

Built to Meet Your Engine’s Demands and Lower Your Costs through Remanufacturing

Starters crank your engine to starting RPM while alternators supply electrical power to operate electrical attachments and/or accessories. New and remanufactured Cat starters and alternators are built to work together to meet the demands of your specific engine and operating environment. 100% quality testing ensures maximum durability and engine starting ability which ultimately lowers your owning and operating costs.

Contact us for more information on Cat starters and alternators and other parts.

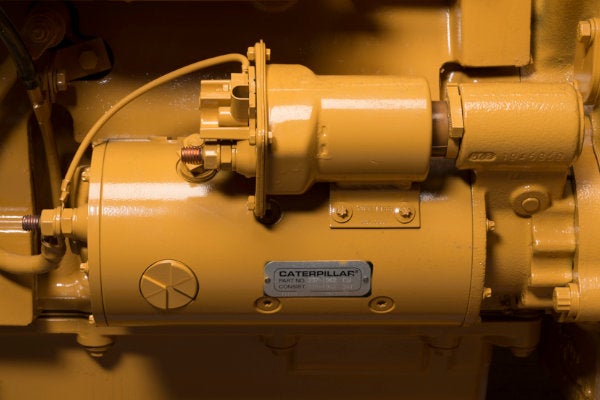

Cat Starters

Cat starters are designed specifically to handle the high current experienced during the cranking of Cat engines. They are built to work hard and deliver reliable performance even in tough, dirty environments. We carry a variety of Cat Starters, matching the torque required with your specific engine.

Cat starters with the PRELUB® system Cat starters with the PRELUB system help to prevent the wear caused by dry starts. This innovative starter combines an oil pump with the body of a conventional starter. The pump automatically draws engine oil from the sump and pressurizes the engine before allowing the starter to crank the engine. Cat starters with the PRELUB system can be easily retrofitted to your machine.

PRELUB® is a registered trademark of RPM Industries.

- Positive-engagement shift mechanism ensures precise pinion-to-ring gear engagement.

- Seamless one-piece solenoid case protects against corrosion.

- Rotatable drive housing allows flexible mounting.

- Brush holder provides constant spring pressure for even wear.

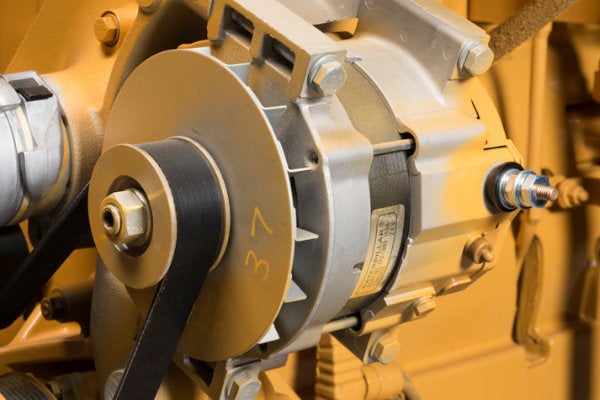

Cat Alternators

Cat alternators are divided into two categories: brush type and brushless. Brush type alternators use one-piece brushes and constant pressure springs for even brush wear. Brushless design alternators feature tighter air gap tolerances and superior sealing for longer life in dusty, dirty environments. Both Cat alternators are superior high-output charging systems that are quiet, compact, and lightweight.

- Built-in electronic voltage regulators

- High-efficiency cooling system

- Brushless design for harsh environments

Did you know you can buy Cat starters and alternators on Parts.Cat.Com? Streamline your parts order today.

Cat Reman Starters and Alternators Reduce Downtime and Costs

When you need repairs, Cat reman starters and alternators get you back to work quickly, reliably, and affordably. Completely remanufactured to include the latest engineering updates, Cat reman starters and alternators provide same-as-new performance and long life.

Strict Remanufacturing Processes

- Components are stripped down to the piece parts

- New O-rings, seals, bushings, and bearings are installed

- Rewound coils are sealed with new insulation

- Heat sink compounds are replaced

- All components that cannot be remanufactured to Caterpillar specifications are replaced with new parts

- Each part is checked individually, and the finished product is performance-tested to ensure it meets like-new specifications.

Coverage and Availability

Cat reman starters and alternators are available off-the-shelf for nearly all Cat engine applications. Coverage includes Cat reman starters with the PRELUB system, as well as a wide amperage range of alternators (up to 145 amps).

Fully Warranted, Low-cost Repair Options

Cat reman starters and alternators are priced at 40-50% of the cost of new parts and provide same-as-new performance and long life. To prove it, Caterpillar backs reman starters and alternators with a same-as-new parts warranty.

WARNING

WARNING